The process starts by putting a batch of rubber into the mill where is passed and rotated between large rollers that are heated. These cost drivers include. how are the raw materials of a pencil processed.

How Are The Raw Materials Of A Pencil Processed, Emissions of BOD and suspended solids are greater for plastic and paper pencils. At the Pencil Factory a Groover machine cuts grooves into the slats to accept the writing core or lead. Waste water effluents The wood pencil emits insignificant quantities of waste water pollutants.

How Pencils Are Made Raw Material Manufacturing Process And Types Artisticaly Inspect The Artist Inside You From artisticaly.com

How Pencils Are Made Raw Material Manufacturing Process And Types Artisticaly Inspect The Artist Inside You From artisticaly.com

Solid waste The wood pencil generates less net process solid waste requiring disposal and less post consumer waste than the other two pencil types. Raw materials and ingredients are sometimes differentiated. Economics of Pencil Making.

The production of polystyrene releases chlorofluorocarbons Schwarz Leisewitz 1999 into the environment- gases that have roughly 1200 times the.

These cost drivers include. The process used in converting raw metals like iron ore into steel involves beneficiation or crushing and separation and smelting the process of heating the ore to obtain the pure metal. Since the electric pencil sharpeners are not frequently used for sharpening pencils they usually keep in a standby condition which will consume powers of the batteries and is not environment protective. The barrel of the pen is made of polystyrene a cheap mass produced plastic. The production of polystyrene releases chlorofluorocarbons Schwarz Leisewitz 1999 into the environment- gases that have roughly 1200 times the.

Another Article :

Source: ivypanda.com

Source: ivypanda.com

Materials and Process Selection for Engineering Design. As such they must meet regulatory requirements safe and legal for your intended use and your specifications contribute to the functionality and quality of your process and product. These cost drivers include. 461 Raw Material Price Trends 462 Pencil Price Trends 463 Product Margins 47 Price Trends 5 Pencil Manufacturing Process 51 Product Overview 52 Detailed Process Flow 53 Various Types of Unit Operations Involved 54 Mass Balance and Raw Material Requirements 6 Project Details Requirements and Costs Involved. The process starts by putting a batch of rubber into the mill where is passed and rotated between large rollers that are heated. Since the electric pencil sharpeners are not frequently used for sharpening pencils they usually keep in a standby condition which will consume powers of the batteries and is not environment protective. How A Mechanical Pencil Is Made 5631 Words Research Paper Example.

Source: calcedar.com

Source: calcedar.com

The level of a raw material or ingredient is the percentage in the formulation. By sharing what we call a material demand profile with the sources of the raw material OEMs can reduce risk for their raw material suppliers enabling them to operate more responsively while increasing the OEMs ability to control pricing and ensure availability. Pencil Sharpeners Plastic Generally pencil sharpeners can be classified into electric pencil sharpeners and manual pencil sharpeners. While the wood pencil. For example when trees are harvested the wood is cut into logs shipped. Cost of raw materials wood graphite clay brass or aluminum for ferrules lacquer components etc cost of parts or other finished components used to assemble the pencil. About Pencil Slats Calcedar.

Source: youtube.com

Source: youtube.com

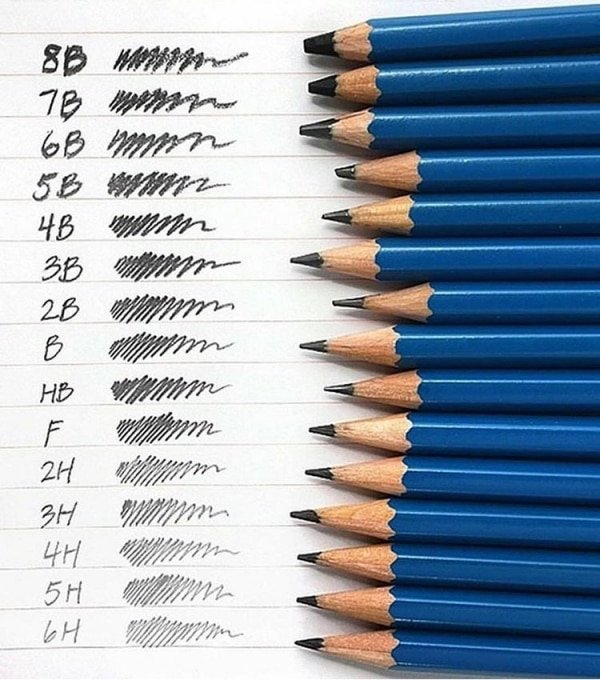

To the core pencils still use graphite that is called lead by the common people. Raw materials and ingredients are sometimes differentiated. For example when trees are harvested the wood is cut into logs shipped. Special wood called the cedar wood is used to make the outer part of the pencil so that it can easily withstand the sharpening of the pencil. The production of polystyrene releases chlorofluorocarbons Schwarz Leisewitz 1999 into the environment- gases that have roughly 1200 times the. The process used in converting raw metals like iron ore into steel involves beneficiation or crushing and separation and smelting the process of heating the ore to obtain the pure metal. How A Pencil Is Made A Behind The Scenes Look At The Faber Castell Pencil Production Process Youtube.

Source: qualitylogoproducts.com

Source: qualitylogoproducts.com

Raw materials and ingredients are sometimes differentiated. To the core pencils still use graphite that is called lead by the common people. These cost drivers include. Next accelerators are added to help fasten the curing process and coloring. Comparing and ranking alternatives I Weighted properties method II For cost corrosion loss etc a lower value is more desirable and the lowest value is rated as 100 minimum value in the list x 100. Coloring pencils may use wax-based cores while many other formulations are used in cosmetic pencils. How Is A Pencil Made What S Inside Quality Logo Products.

Source: madehow.com

Source: madehow.com

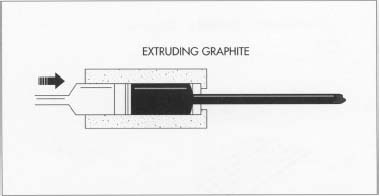

The process used in converting raw metals like iron ore into steel involves beneficiation or crushing and separation and smelting the process of heating the ore to obtain the pure metal. Processing of raw materials like trees may involve an entirely different process. The process starts by putting a batch of rubber into the mill where is passed and rotated between large rollers that are heated. Materials and Process Selection for Engineering Design. Writing cores made from a mixture of graphite and clay are placed into the grooves. Pencil Sharpeners Plastic Generally pencil sharpeners can be classified into electric pencil sharpeners and manual pencil sharpeners. How Pencil Is Made Material Manufacture Making History Used Processing Steps Product Machine.

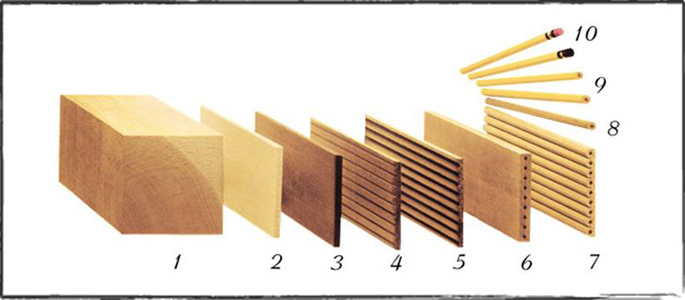

Source: calcedar.com

Source: calcedar.com

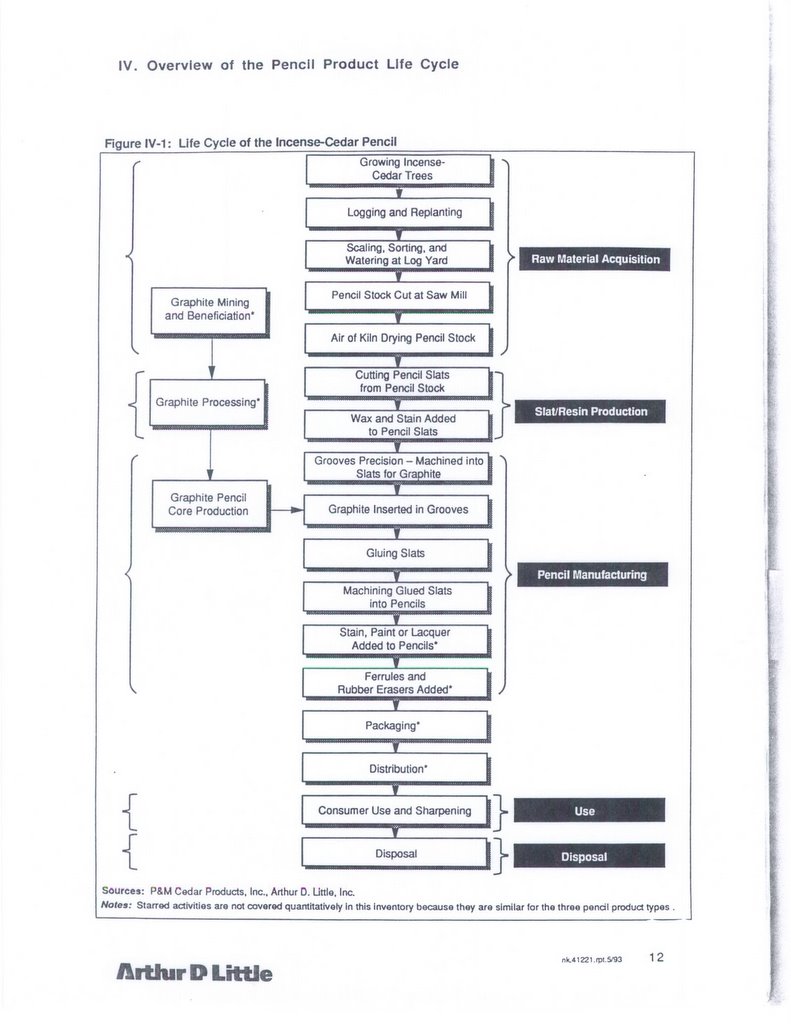

The cap barrel and ink tube are made of plastic while the ballpoint and tip are made of metals. 1 Calculate and share detailed raw material demand forecasts at regular intervals with service centers and mills. Coloring pencils may use wax-based cores while many other formulations are used in cosmetic pencils. Since the electric pencil sharpeners are not frequently used for sharpening pencils they usually keep in a standby condition which will consume powers of the batteries and is not environment protective. Raw materials and ingredients are sometimes differentiated. Processing of raw materials like trees may involve an entirely different process. Pencils An Environmental Profile Calcedar.

Source: prezi.com

Source: prezi.com

Processing of raw materials like trees may involve an entirely different process. These cost drivers include. The production of polystyrene releases chlorofluorocarbons Schwarz Leisewitz 1999 into the environment- gases that have roughly 1200 times the. Solid waste The wood pencil generates less net process solid waste requiring disposal and less post consumer waste than the other two pencil types. The process used in converting raw metals like iron ore into steel involves beneficiation or crushing and separation and smelting the process of heating the ore to obtain the pure metal. The graphite is mixed with water and clay to form the pencil lead. How A Pencil Is Made And Its Environmental Impacts By Ashley Ge.

Source: artisticaly.com

Source: artisticaly.com

Detailed Project Reports Profiles on Pencil Sharpeners plastic - Manufacturing Plant Detailed Project Report Profile Business Plan Industry Trends Market Research Survey Manufacturing Process Machinery Raw Materials Feasibility Study. By sharing what we call a material demand profile with the sources of the raw material OEMs can reduce risk for their raw material suppliers enabling them to operate more responsively while increasing the OEMs ability to control pricing and ensure availability. Raw materials and ingredients are sometimes differentiated. Raw materials ingredients processing aids and packaging materials are the foundation of finished food products. Economics of Pencil Making. For example when trees are harvested the wood is cut into logs shipped. How Pencils Are Made Raw Material Manufacturing Process And Types Artisticaly Inspect The Artist Inside You.

Source: qualitylogoproducts.com

Source: qualitylogoproducts.com

Pencil Sharpeners Plastic Generally pencil sharpeners can be classified into electric pencil sharpeners and manual pencil sharpeners. Economics of Pencil Making. The process starts by putting a batch of rubber into the mill where is passed and rotated between large rollers that are heated. Raw Materials. The cap barrel and ink tube are made of plastic while the ballpoint and tip are made of metals. As such they must meet regulatory requirements safe and legal for your intended use and your specifications contribute to the functionality and quality of your process and product. How Is A Pencil Made What S Inside Quality Logo Products.

Source: qualitylogoproducts.com

Source: qualitylogoproducts.com

Comparing and ranking alternatives I Weighted properties method II For cost corrosion loss etc a lower value is more desirable and the lowest value is rated as 100 minimum value in the list x 100. The wood is cut into thin slabs as thick as the pencil. The second step in a pencils lifecycle is to process the raw materials. The level of a raw material or ingredient is the percentage in the formulation. Coloring pencils may use wax-based cores while many other formulations are used in cosmetic pencils. The process used in converting raw metals like iron ore into steel involves beneficiation or crushing and separation and smelting the process of heating the ore to obtain the pure metal. How Is A Pencil Made What S Inside Quality Logo Products.

Source: qualitylogoproducts.com

Source: qualitylogoproducts.com

In this book raw materials includes both and mean all materials used in the process. The latex rubber is mixed with chemicals and colored pigments to form the eraser. Emissions of BOD and suspended solids are greater for plastic and paper pencils. Since the electric pencil sharpeners are not frequently used for sharpening pencils they usually keep in a standby condition which will consume powers of the batteries and is not environment protective. The second step in a pencils lifecycle is to process the raw materials. Materials and Process Selection for Engineering Design. How Is A Pencil Made What S Inside Quality Logo Products.

Source: madehow.com

Source: madehow.com

Special wood called the cedar wood is used to make the outer part of the pencil so that it can easily withstand the sharpening of the pencil. Raw materials and ingredients are sometimes differentiated. The level of a raw material or ingredient is the percentage in the formulation. Writing cores made from a mixture of graphite and clay are placed into the grooves. Economics of Pencil Making. Just as with any other manufactured products the economics of pencil manufacturing are driven by a number of factors. How Pencil Is Made Material Manufacture Making History Used Processing Steps Product Machine.

Source: artisticaly.com

Source: artisticaly.com

Raw materials ingredients processing aids and packaging materials are the foundation of finished food products. Then sulfur is added to this mixture that acts as a curing agent. 461 Raw Material Price Trends 462 Pencil Price Trends 463 Product Margins 47 Price Trends 5 Pencil Manufacturing Process 51 Product Overview 52 Detailed Process Flow 53 Various Types of Unit Operations Involved 54 Mass Balance and Raw Material Requirements 6 Project Details Requirements and Costs Involved. These cost drivers include. Since the electric pencil sharpeners are not frequently used for sharpening pencils they usually keep in a standby condition which will consume powers of the batteries and is not environment protective. Processing of raw materials like trees may involve an entirely different process. How Pencils Are Made Raw Material Manufacturing Process And Types Artisticaly Inspect The Artist Inside You.

Source: youtube.com

Source: youtube.com

The level of a raw material or ingredient is the percentage in the formulation. At the Pencil Factory a Groover machine cuts grooves into the slats to accept the writing core or lead. Coloring pencils may use wax-based cores while many other formulations are used in cosmetic pencils. The wood is cut into thin slabs as thick as the pencil. Raw materials as the primary products from agricultural and marine sources and ingredients as processed materials. Pencil Sharpeners Plastic Generally pencil sharpeners can be classified into electric pencil sharpeners and manual pencil sharpeners. How A Pencil Is Made A Behind The Scenes Look At The Faber Castell Pencil Production Process Youtube.

Source: qualitylogoproducts.com

Source: qualitylogoproducts.com

Detailed Project Reports Profiles on Pencil Sharpeners plastic - Manufacturing Plant Detailed Project Report Profile Business Plan Industry Trends Market Research Survey Manufacturing Process Machinery Raw Materials Feasibility Study. To the core pencils still use graphite that is called lead by the common people. Raw materials and ingredients are sometimes differentiated. Economics of Pencil Making. As such they must meet regulatory requirements safe and legal for your intended use and your specifications contribute to the functionality and quality of your process and product. Waste water effluents The wood pencil emits insignificant quantities of waste water pollutants. How Is A Pencil Made What S Inside Quality Logo Products.